8th December 2022

“CREATING A SLOW TOURBILLION – WHY IT’S WORTH THE EFFORT”.

DAVID COTTRELL

How fortunate we were that David Cottrell was available to accept the invitation to speak to the South London Branch for this, “The George Daniels Memorial Lecture”.

A former BorgWarner precision toolmaker, with no horological experience, David read “Watchmaking” by George Daniels. A 2013 Christmas gift, from his wife. Nine years later he is showing us his first and second watches, explaining how he designed and made an exquisite four-minute tourbillion, with separate drive to the second’s hand. The single-minded dedication and perseverance are hard to imagine.

After making his first watch, a minute tourbillion with Daniels Coaxial escapement, David studied the Derek Pratt remontoir/tourbillion idea and the physics behind the concept which has the advantage of isolating the escape wheel from rotational inertia of the carriage. He then designed on CAD a four-minute tourbillion, the slower rotational speed being another approach to reducing the energy in the system and hence loading on the escape wheel during locking. Shock protection for the carriage support was achieved with David’s unique design of a swan neck bracket. The weight of the carriage was 3g and the swan neck bracket was tested to a weight of 15g to simulate a 5G shock. For the second watch David decided to machine a Roger Smith one piece type escape wheel from silver steel. He discussed and showed the tool making processes to make constant form relief cutters for the locking teeth. The inner, raised, impulse teeth were profiled using a 0.5mm cutter. To machine some of the complex curved parts was challenging without the assistance of CNC.

When making parts it is often necessary to record a specific temperature to harden and temper the part and then to measure the hardness of the finished piece. These processes require prohibitively expensive instruments which may be used just occasionally. So, David took us through the prosses of designing and making his own hardness tester. This was driven by the need to ensure that the form relieved cutters made for the escape wheel would retain their edge. Heat treatment of these cutters proved to be critical, with a narrow temperature range – 806 and 816C. To check the accuracy of a furnace he passed on a tip that table salt, conveniently melts at 800c. Another little detail was he likes to make the screws with curved heads where appropriate.

Duncan thanked David for a very technical and inspiring lecture which was followed by many questions from the audience and a presentation of the appropriate lubricant. To give an idea of the quality of the workmanship, you might like to google www.instagram.com/djcotterellwatches.

Was it worth the effort? It sure was!!!

-Duncan Greig

Doors open at 19:30, Starting 20.00 hours.

For those of you not able to attend log in details will be sent in a separate email. Please log in from 19:40 .

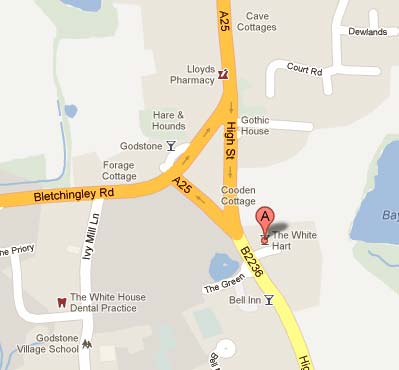

The meeting will be held at The White Hart Barn in Godstone.

THE WHITE HART BARN (Godstone Village Hall)

GODSTONE

SURREY RH9 8DU

7.30pm for 8.00pm Start