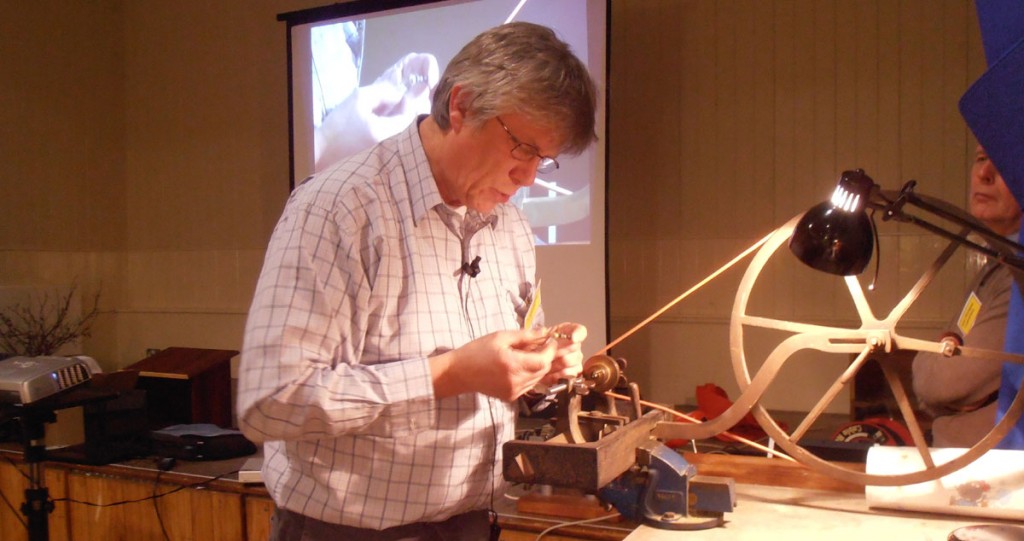

Working between centres is an essential skill in horology. Duncan Grieg described his methods to a keen audience at a Branch meeting in 2013. This demonstration is described below and videos can be seen here.

Not only did Duncan bring along a bench but also also a selection of traditional clock and watchmakers’ turning tools. He started the demonstration by fitting a contrate wheel to an arbor using a beautifully preserved 19th century clockmakers’ throw.  As the work is held between centres, it is necessary to fit a carrier. Whilst fitting the carrier, Duncan explained that many old clock arbors have a small chamfer turned at each shoulder so that the arbor can be spun between centres without stressing the pivots. He added that the throw has a significant advantage over a chuck lathe as the work can easily be removed for inspection and then put back – safe in the knowledge that the work will be running exactly as before.

As the work is held between centres, it is necessary to fit a carrier. Whilst fitting the carrier, Duncan explained that many old clock arbors have a small chamfer turned at each shoulder so that the arbor can be spun between centres without stressing the pivots. He added that the throw has a significant advantage over a chuck lathe as the work can easily be removed for inspection and then put back – safe in the knowledge that the work will be running exactly as before.

Once the carrier and the arbor were fitted into place Duncan began to turn the collet for the contrate wheel. Whilst spinning the hand-wheel, Duncan described how he was cutting back a gentle taper to find the right diameter for the wheel, then he repeatedly removed the work to check against the wheel. When the right diameter was achieved he turned the side of the collet straight, removed the work once more and pushed the wheel home. Re-mounted the wheel and arbor between centres and then using a burnisher rubbed over the end of the collet to hold the wheel good and tight. The contrate wheel was then passed around the audience to see the slightly domed burnished collet end that was immovably holding the wheel to the arbor.

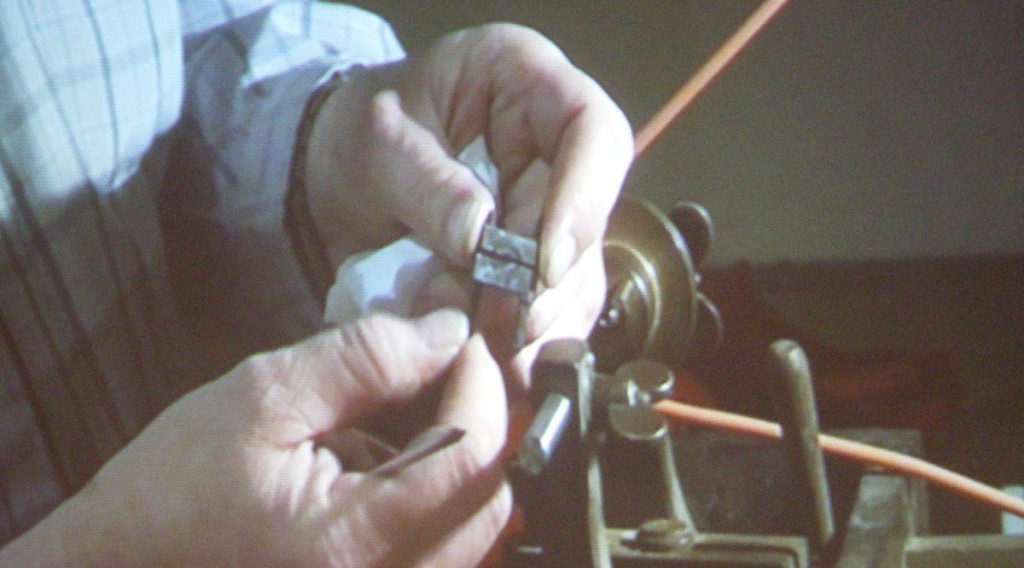

Duncan then showed a smaller bow lathe, which he admitted was perhaps not always commercially viable to use in the modern day workshop, but was nonetheless very enjoyable to own. A tool Duncan employs regularly in his workshop is the modern set of Swiss watchmaker’s turns which formed the next part of his demonstration. Duncan mainly uses these to support components whilst polishing them. He uses various custom made brass runners for this but demonstrated the tuning of a steel spacer.

The spacer was mounted to a carrier in the form of a tapered steel arbor with integral pulley wheel. Before fitting the carrier between the centres, he laid the hair of the bow across the bed of the turns. Once the work is fitted he can then simply pull the bow upwards setting the hair on the pulley and by rotating the bow wrap the line tightly around the pulley. He turned the piece, only cutting on the down-stroke of the bow, whilst explaining that he found the small turns very useful for everyday work and used them a lot.

The spacer was mounted to a carrier in the form of a tapered steel arbor with integral pulley wheel. Before fitting the carrier between the centres, he laid the hair of the bow across the bed of the turns. Once the work is fitted he can then simply pull the bow upwards setting the hair on the pulley and by rotating the bow wrap the line tightly around the pulley. He turned the piece, only cutting on the down-stroke of the bow, whilst explaining that he found the small turns very useful for everyday work and used them a lot.

The final stage of Duncan’s demonstration was to burnish the pivot of an old cylinder assembly on the Jacot tool. He used the balance as a carrier for this procedure and cautioned the audience that it was all too easy to remove material from tiny pivots and it was worth checking progress regularly.

Duncan joked modestly that he should not be trusted with anyone’s watch but the pivot remained intact and gained a bright burnished finish.